Chapter II:

Use of Microorganisms in Food

Fermentations

2.1. Bread

The four

ingredients used in bread-making are flour, water, salt, and yeast or

sourdough. For 100 kg of flour, the ingredient proportions are 62 liters of

water, 2 kg of yeast, and slightly less than 2 kg of salt. These proportions

may vary depending on the type of bread desired. Traditional bread, for

example, is often more hydrated, with between 65 and 70 liters of water per 100

kg of flour.

2.1.1. Characteristics of the Ingredients:

- 2.1.1.1. Flour: It is the

essential element. Firstly, mixing flour with water allows the formation

of dough. Secondly, the quality, characteristics, and properties of flour

have a direct impact on bread. Flour determines the bread’s taste, color,

and texture. Bakers sometimes use carefully formulated ready-made blends

from millers, called "mixes," designed to produce specific types

of bread (such as multigrain bread). Each type of bread requires a

specific type of flour.

- 2.1.1.2. Water: By moistening

starch and gluten particles, water enables the formation of an elastic

gluten network that binds all other flour components together. Without

water, the dough would not be able to retain carbon dioxide during

fermentation. Water plays a crucial role in the dough’s plasticity and

helps dissolve the salt.

- 2.1.1.3. Salt: It plays a very

important role in the "chemistry of bread." Salt enhances the

dough’s consistency; when incorporated at the beginning of kneading, it

slows down oxidation, thus preventing loss of flavor. It contributes to

the bread’s taste, enhances the crust’s color, and affects its

preservation.

- 2.1.1.4. Yeast: Baker’s yeast is

a microscopic fungus of natural origin, Saccharomyces cerevisiae.

One gram of fresh yeast contains 9 to 10 billion cells. Yeast can survive

with or without air, and its preferred food is simple sugar, glucose. This

biological agent allows the dough to rise by transforming sugars into

carbon dioxide and alcohols, which evaporate during baking. Without yeast, bread would be flat.

The storage

conditions of yeast are very important: if stored at too low or, more

critically, too high a temperature, it loses its fermentation power.

2.1.2. The

Eight Stages of Breadmaking

Artisan

bakers oversee the entire bread-making process, from production to final sale

to the consumer. Each baker has their own technique, but the main stages of

breadmaking remain the same.

2.1.2.1.

Kneading:

The baker

mixes all the dough ingredients. The gluten in the flour absorbs the water

poured into the mixing bowl. The dough becomes elastic and traps air. If a

mechanical mixer is used, it facilitates this crucial stage, but the baker must

remain vigilant and closely monitor the process. Different kneading methods are

possible. Slow-speed kneading produces a less developed bread, while

intensified kneading, which is longer and has a higher rotation speed, results

in very well-developed bread with a thin crust. Improved kneading, a balance

between these two methods, lasts 10 to 15 minutes and includes rest periods of

2 to 3 minutes. For proper fermentation, the baker must ensure the dough

reaches a final temperature of 23 to 25°C; if necessary, the water is cooled.

2.1.2.2.

First Fermentation (Pointage):

Before

dividing the dough, the baker lets it rest in the mixing bowl. This step, known

as pointage, is crucial for developing the bread’s aroma. The production of

carbon dioxide begins, causing the dough to rise and its qualities to improve,

making it more elastic. For traditional bread, this step takes longer. The

baker’s experience helps determine when the dough is ready, as every dough

reacts differently based on daily variables (such as air humidity). The baker

touches the dough with their fingertips and decides if it's time to move to the

next stage.

Note: No machine, no matter how advanced, can

replace the baker’s hand.

2.1.2.3.

Scaling (Pesée):

Once the

dough has finished fermenting, the baker divides it into dough pieces (pâtons)

of the desired weight. A dough divider is often used, though it slightly

reduces the dough’s flexibility. To compensate for this, the baker allows the

dough to rest again.

2.1.2.4.

Shaping (Façonnage):

By hand or

with a machine, the baker shapes each dough piece to give it the desired bread

form. This movement is called la tourne. The shaped loaves are placed on baking

nets or in small cloth-lined baskets designed for their shape (long for

baguettes, round for country loaves).

2.1.2.5.

Proofing (Apprêt):

Proofing is another resting period where

the shaped dough undergoes further fermentation. During this stage, the yeast

continues feeding on the sugars in the dough, releasing carbon dioxide. Trapped

within the gluten structure, the gas causes the dough to rise, tripling its

volume. The proofing time depends on temperature, yeast quantity, kneading

method, and initial fermentation time, ranging from one to four hours. Some

bakers use temperature-controlled proofing chambers.

2.1.2.6.

Loading into the Oven (Enfournement):

Meanwhile,

the oven is preheated to 250°C. Before placing the dough inside, the baker

injects steam to keep the bread from drying out, ensuring a thin, golden crust.

Before baking, the baker scores the dough’s surface with a blade to allow

carbon dioxide to escape.

2.1.2.7.

Baking (Cuisson):

Baking time

varies depending on the bread's shape and weight, ranging from 12 to 50

minutes. In the early stages of baking, the dough continues to rise as the

crumb forms and solidifies. The crust hardens and develops its final color.

2.1.2.8.

Unloading from the Oven (Défournement):

The bread is

carefully removed from the oven as it is fragile while still hot. It must cool

properly to allow moisture and carbon dioxide to escape. During this period,

the loaves should be stored in a dry, well-ventilated room.

2.1.3.Role

of Microorganisms in Breadmaking

Bread is

made from flour, yeast or sourdough, salt, and water. Sourdough is a fermenting

dough with an acidic reaction. It contains an acidifying microflora, primarily

composed of yeasts (Saccharomyces cerevisiae).

The yeast Saccharomyces

cerevisiae plays a crucial role during the kneading of the bread dough. It

produces chemical substances that modify the structure of gluten, thereby

altering the dough’s texture. The yeast breaks down sugars and converts them

into carbon dioxide and alcohol, causing the dough to rise. During baking, the

carbon dioxide bubbles remain trapped, while the alcohol evaporates. This

process gives the bread its final texture.

2.2. Cheese Making

Cheeses are

made from different types of milk (sheep, cow, goat), either pure or mixed.

Originally, cheese making was a way to preserve milk, allowing only the solid

part of the milk to be stored after transformation. The process involves

several steps depending on the characteristics of the final product desired.

2.2.1. What

is Lactic Fermentation?

Lactic

fermentation is a chemical reaction between bacteria and milk. The bacteria

consume lactose (the sugar in milk) and produce lactic acid, which gradually

coagulates casein (the milk protein). The fermentation process stops when the

mixture is refrigerated

2.2.2. Steps

of Cheese Making

2.2.2.1. Coagulation: Lactic ferments or rennet are added to

the milk to cause coagulation, dividing it into two parts:

- Curd (solid part),

used to make cheese.

- Whey (liquid part),

often used as animal feed.

2.2.2.2. Draining: The curd contracts, and the whey is

drained. This separation happens naturally but can be accelerated by stirring,

cutting, or heating.

2.2.2.3. Molding:

The curd is shaped using perforated molds or by pressing it into cloth-lined

wooden or other material frames.

2.2.2.4. Pressing: This step removes excess water by

applying weight to the mold. It is optional and depends on the type of cheese

being produced.

2.2.2.5. Salting:

Salt is either incorporated into the cheese or applied to its surface to

control the development of specific microorganisms.

2.2.2.6. Aging: For fresh cheeses, the process ends after

draining. However, for other cheeses, the aging process begins, lasting from

several days to months. During this period, fermentation transforms the curd

into cheese, giving it its flavor and aroma. Cheese is carefully handled

(turned, brushed, etc.), and temperature and humidity significantly affect

aging, determining the final taste and texture.

This final stage occurs in a cellar, where

the development of aging agents is monitored and controlled depending on the

type of cheese being produced.

2.2.3. Examples of

Microorganisms Used in Cheese Making

- Camembert : Penicillium camembertii

- Munster: Washed with

salted water, Brevibacterium linens

- Roquefort: Penicillium

roqueforti, requires oxygen for growth

- Emmental: Two bacteria

work together—one (a lactic bacterium) produces lactate, while the other

(a propionic bacterium) consumes it and releases CO₂, forming

characteristic holes in the cheese. Microorganisms

also play a role on the cheese surface.

Camembert Emmental

Camembert Emmental

2.2.2. Factors

Controlling the Development of Microorganisms

The development of these microorganisms depends on:

- pH: Microorganisms are more or less sensitive to

acidity. This factor is used as early as the coagulation stage to prevent

the growth of pathogens.

- Salting: This affects the

amount of free water available for microorganisms.

- Humidity (Hygrometry): This refers to

the moisture content in the air (the amount of water in gaseous form). In

cheese-aging cellars, humidity is usually high (around 80–95%). Lowering

humidity limits the growth of bacteria, then yeasts, and finally molds.

- Oxygenation: Proper aeration

promotes the development of aerobic microorganisms.

- Temperature: The temperature

in the cellar is maintained between 10 and 12°C to support microbial

activity.

2.2.3. Conclusion

In cheese production, all types of

microorganisms play a role. They serve various functions, including protecting

the cheese from harmful microorganisms by acidifying the environment. During

aging, they are essential in transforming the cheese, giving it its distinct

taste, texture, and character.

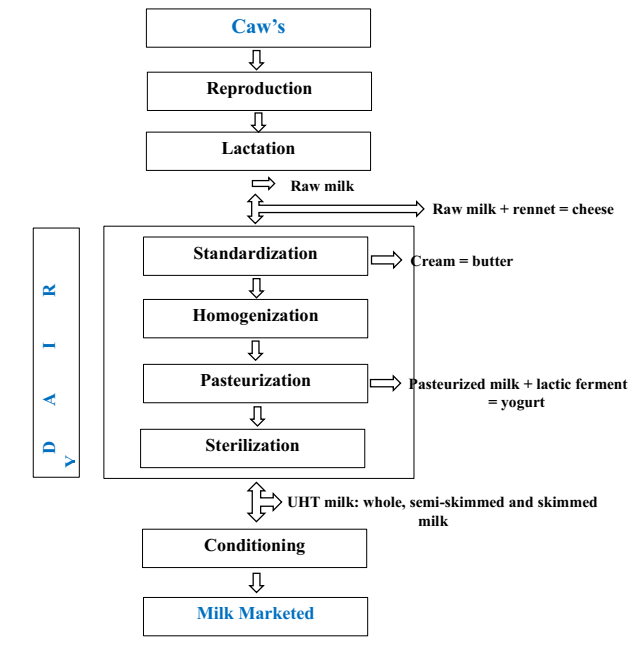

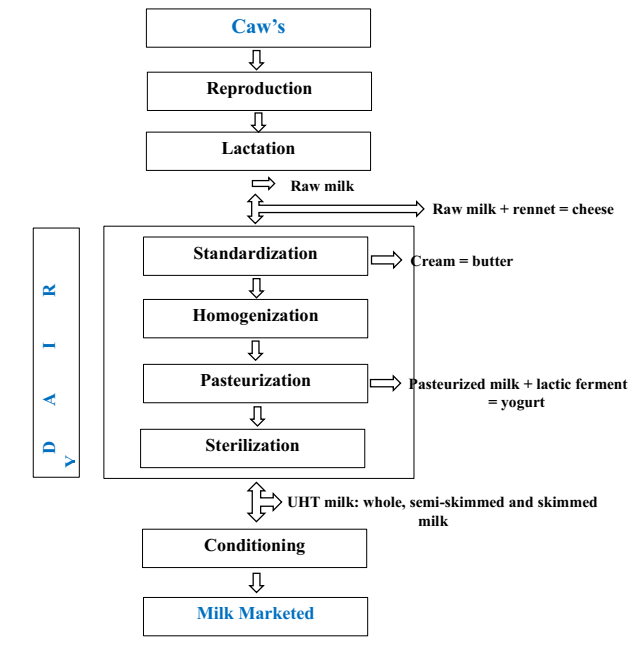

2.3. Milk:

2.3.1. Milk composition

Milk is a complex liquid primarily composed of

water and four key constituents, whose proportions vary depending on species

and breeds. For example, the average composition of cow’s milk is as follows:

- Water : 87.5%

- Carbohydrates :

4.9%

- Lipids: 3.6%

- Proteins: 3.4%

- Minerals: 1%.

2.3.2. Dairy products

Dairy products can be made from cow’s milk,

goat’s milk, or sheep’s milk. There is a wide variety of dairy products, including:

- Cream, either raw or

pasteurized, obtained after skimming the milk.

- “Cream”: at least 30% fat

content in milk

- “Light cream”: at least 12% fat

content

- Butter, obtained after cream

maturation and churning. It must contain 82% fat, 16% water, and 2%

non-fat dry matter.

- Yogurt (or yoghurt),

obtained by fermenting milk with Lactobacillus bulgaricus and Streptococcus

thermophilus bacteria. Pasteurization is mandatory. Fermented milk

using other bacteria is not considered yogurt.

- Fresh cheeses (White cheese , a

small creamy fresh cheese, etc.), which are non-aged cheeses obtained

through lactic fermentation.

- Dairy desserts, composed of at least

50% milk (dessert creams, rice pudding, etc.).

- Cheeses, made by coagulating

milk, draining the curd, and sometimes undergoing an aging process. There are eight

families of cheese:

- Processed cheese

- Fresh cheese

- Soft cheese with a bloomy rind

- Soft cheese with a washed rind

- Blue cheese

- Cooked pressed

cheese

- Uncooked pressed

cheese

- Goat cheese.

2.3.3. Milk

Quality and Yield:

The quality of milk collected on farms can be

analyzed based on the following criteria:

- Physical quality: The milk must be free

from any impurities.

- Chemical quality: Fat and protein

content.

- Bacteriological quality: Enumeration of total aerobic mesophilic flora, which should be as

low as possible.

- Absence of pathogenic germs (Brucella, Listeria, etc.).

2.3.4. Factors Influencing Yield Improvement:

Milk yield improvement mainly depends on the following

factors:

✔ Quality of raw

materials: Optimization of animal feed, livestock selection, milking

hygiene, and milk storage cleanliness.

✔ Control of

manufacturing processes: Monitoring acidification, temperature, etc.

✔ Proper adjustment and functioning of

equipment (e.g., skimmers).

The conversion yield is a crucial

criterion for assessing the profitability of a dairy production unit.

|

|

Dairy Products

|

Milk Quantity Required

|

|

Cow’s Milk:

|

1L of cream

|

10L of milk

|

|

1kg of butter

|

20L of milk

|

|

1kg of fresh cheese

|

2-3L of milk

|

|

8 pots of yogurt (125g each)

|

1L of milk

|

|

1kg of aged pressed cheese

|

10-12L of milk

|

|

Goat’s Milk:

|

1kg of fresh lactic cheese

|

6-7L of milk

|

|

1kg of semi-dry lactic

cheese

|

8L of milk

|

|

1kg of dry lactic cheese

|

9.5L of milk

|

|

1kg of pressed cheese

|

10-11L of milk

|

|

Sheep’s Milk:

|

1kg of lactic cheese

|

3-4L of milk

|

Once collected from farms, the milk is

transported to the dairy where it will be processed into consumer milk and

dairy products. However, before being processed, the milk arriving at the

factory must go through a reception process. The reception takes place in a

dedicated room and involves two operations: measuring and pouring.

The milk is then examined, tasted, and, if

necessary, a sample is taken to measure its acidity, ensuring that acidic milk

unfit for consumption is set aside.

2.3.5. Milk Treatments

Raw milk, as collected from the farm, can only

be stored in the refrigerator for up to 48 hours and is only safe for

consumption if boiled. Therefore, to extend its shelf life and make it directly

consumable, this milk, which is transported to the dairy in a refrigerated

truck (4°C), must undergo thermal and physical treatments.

2.3.5.1. Standardization

Standardization is the first treatment applied

to raw milk. Since milk composition varies depending on diet, seasons, and cow

breeds, its fat content (FC) can range from 30 to 70g/L.

A standardizing separator is used to unify the

composition of milk from different farms and to adjust the fat content

according to legal requirements for consumer milk and dairy products. This

process involves separating the cream from the milk by centrifugation and then

reintroducing it according to the required fat content:

Whole milk is obtained by reintroducing more

than 3.25% fat.

Semi-skimmed milk is obtained by reintroducing

approximately 1.7% fat.

Skimmed milk is obtained by reintroducing 0.1%

to 0.3% fat.

Standardization allows milk to be artificially

adjusted to a fixed fat content while ensuring it retains sufficient

nutritional value.

2.3.5.2. Homogenization

This treatment, which follows standardization,

aims to prevent fat from rising to the surface, which could disrupt milk flow

or cause deposits on the packaging during subsequent thermal preservation

treatments. The process is simple: it involves breaking fat globules into fine,

uniform particles using pressure.

Depending on the required shelf life and

bacteriological condition, the standardized and homogenized milk then undergoes

thermal treatments: either pasteurization or sterilization.

2.3.5.3. Pasteurization

Pasteurization is a thermal treatment designed

to eliminate pathogenic germs that cause diseases. There are two types of

pasteurization:

Low-temperature slow pasteurization, where the

milk is heated for 30 minutes at a temperature between 63 and 65°C or for 5

minutes at 68°C.

High-temperature pasteurization, where the milk

is heated for 15 seconds at a temperature between 72 and 75°C and then

immediately cooled.

Since pasteurized milk is not sterile, it must

be immediately cooled to 3°C. Afterward, the milk is pressurized, meaning it is

stored at normal atmospheric pressure and bottled. This results in pasteurized

milk that can be stored in the refrigerator for up to 7 days.

2.3.5.4. Sterilization

Unlike pasteurization, this thermal treatment

destroys all milk germs, whether pathogenic or not. Milk sterilized using the

classic method is heated to 115°C for 15 to 20 minutes and can be stored for 4

months. As for Ultra-High Temperature (UHT) sterilized milk, it is heated to

140°C for 2 to 3 seconds and can be stored for 3 months.

Ultimately, all these thermal and physical

treatments make it possible to produce a wide range of consumer milk products

available in stores.

Fig

01: Cow's milk cycle to marketing.

2.4. Others

2.4.1. Lacto-Fermented Vegetables

Lactic fermentation is not only used for preserving

dairy products; it also allows for the preservation of mushrooms and various

vegetables such as cabbage, beetroot, carrot, beans, onion, etc. This technique

involves preserving vegetables by promoting the development of lactic acid

bacteria, which acidify the environment and inhibit the growth of undesirable

organisms.

For fermentation to occur, all the necessary

conditions for the development of lactic acid bacteria must be met. Vegetables

must provide sugar, B-group vitamins, and minerals. Since fermentation takes

place in an anaerobic environment, oxygen must be eliminated; to achieve this,

vegetables are often covered with salted water (as salt inhibits bacteria

responsible for vegetable decomposition). Finally, the temperature should be

between 18 and 22°C at the beginning of fermentation.

Fermentation then proceeds through three phases:

- Pre-fermentation, lasting 2–3 days,

during which various microorganisms develop, leading to the decomposition

and softening of the vegetables.

- Fermentation, which begins when

lactic acid bacteria dominate over other microorganisms.

- Storage, when the pH drops below

4. At this stage, undesirable microorganisms can no longer develop, and

new flavors emerge.

The vegetables can then be preserved for at

least a year, even if the temperature rises above 10°C. This preservation

method is not only economical, as it requires no energy input, but also

beneficial to health since lactic acid bacteria produce numerous vitamins and

lactic acid, which has various digestive benefits.

2.4.2. Acetic Fermentation

Acetic acid is

formed by the oxidation of alcohol through the oxygen in the air. Wine, beer,

cider, and generally all fermented alcoholic liquids turn sour when exposed to

air. Louis Pasteur, relying on the experiments of vinegar makers of his time

and on the effects of fermentation, determined the nature of the ferment

involved. He demonstrated that the ferment is a living organism, which he named

Mycoderma aceti (vinegar mother). He observed its multiplication in all

directions and conducted numerous experiments to prove that Mycoderma aceti

was the sole ferment responsible for vinegar production. The simplified acetic

fermentation reaction is:

CH₃-CH₂-OH + O₂ → CH₃-COOH + H₂O + Energy

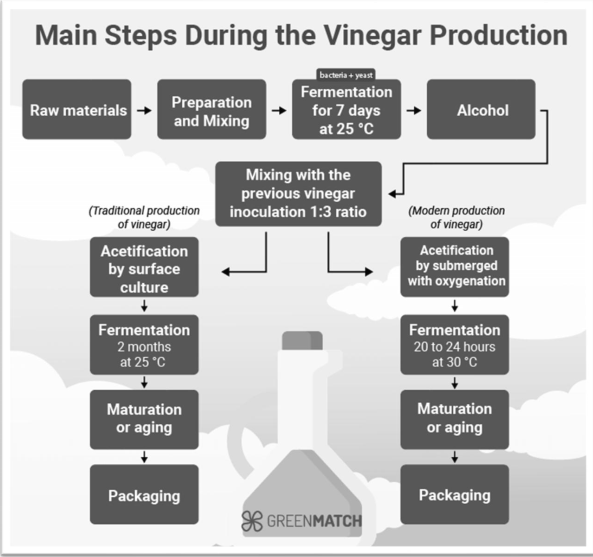

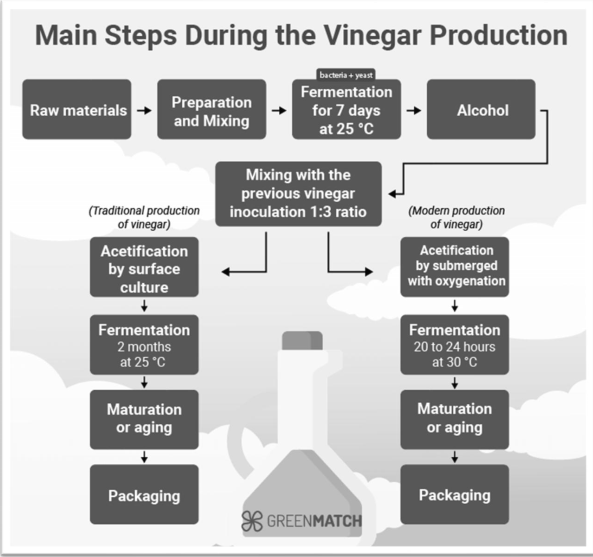

2.4.2.1. Vinegar Production

There are several methods for producing vinegar, one of which is the Orléans

method. This method involves cultivating Acetobacter aceti by mixing

wine and vinegar in a ventilated barrel. The bacteria primarily develop at the

air-liquid interface, meaning on the surface. This is a static culture method.

Today, this method is used to produce traditional and high-quality vinegar.

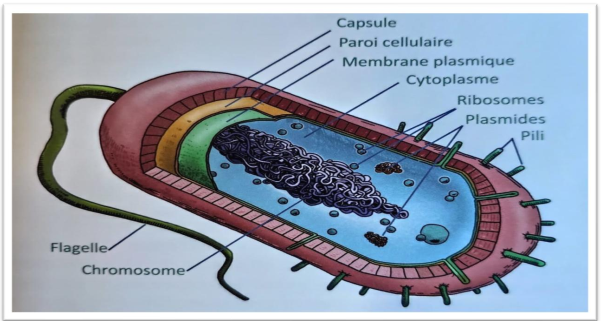

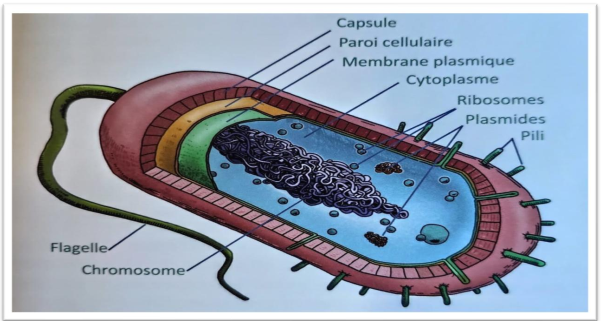

Fig 02: the bacterium Acetobacter

aceti.

Since Pasteur's

research, the bacterium Acetobacter aceti has been cultivated in a

controlled manner for industrial vinegar production. The fermentation process

has been accelerated; whereas it previously took three weeks, it is now

possible to produce large quantities of vinegar in just 24 hours.

The industrial

method involves using a bioreactor that operates with a high level of aeration

and bacteria immersed in the culture solution. Industrial vinegar production

follows different processes, summarized in the following diagram:

Fig 03: Diagram showing

the different stages of vinegar production.

Vinegar can be made from various raw materials,

including grapes, rice, apples, berries, cereals, whey, or honey.

Legislation regarding the designation of vinegar

varies by country:

- In Europe, the acetic acid concentration must be at least 60 g/L.

- In the United States, it must be at least 40 g/L.